We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

A Guide To Flexible Metal Conduit

A Guide To Flexible Metal Conduit

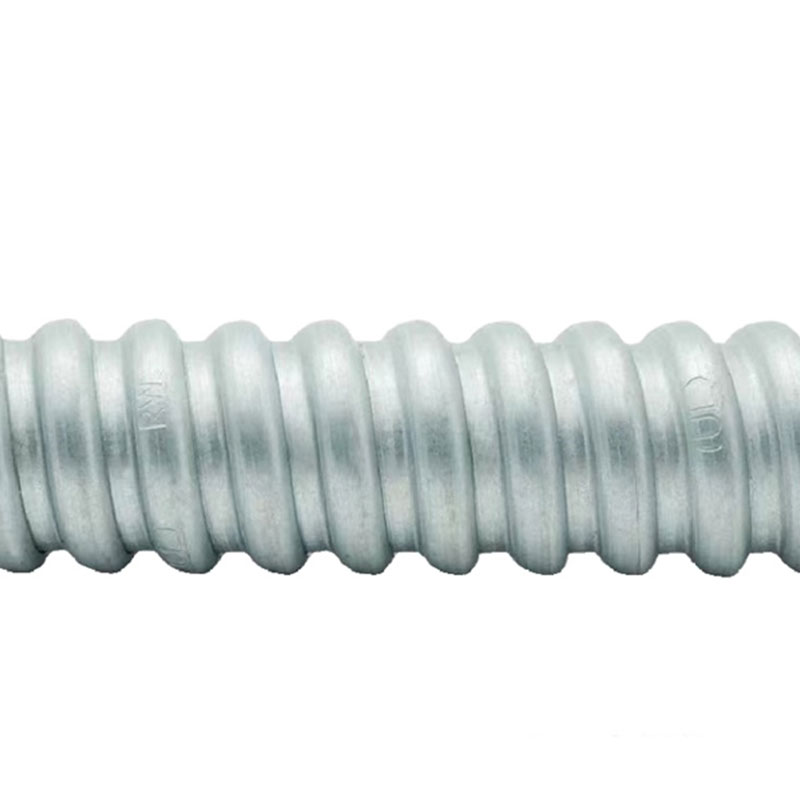

Flexible metal conduit is an electrical conduit made of flexible metal tubing. It is used to protect wires in exposed or potentially hazardous areas. Flexible metal conduits are available in a variety of sizes, lengths and materials. The most common type is made of galvanized steel, but it can also be made of stainless steel, aluminum or copper.

Flexible metal conduit is typically used in applications that require protection from physical damage, chemical exposure, or overheating. It is typically used in industrial settings such as oil refineries and power plants.

Flexible metal conduit can be installed using a variety of methods, including screwing it into place, welding it to another piece of metal, or securing it with clips.

A Guide To Flexible Metal Conduit

We are a professional PPR pipe manufacturer.LUELLYA manufactures PPR pipes using quality proven materials from our reliable supplier network, whose consistent material quality ensures consistent manufacturing cycles. Our PPR pipes are ready to be installed wherever they are delivered, as they have passed all quality standards through comprehensive testing in our full facility.

We reduce waste build-up and pollution in our manufacturing process by adhering to strict production standards and using recyclable PPR. Rigorous inspections are carried out at every stage to prevent hygiene and quality issues with our PPR pipes, ensuring product safety and quality are maintained while in use. "

Can split flexible conduit be used for electrical wiring?

Yes, these conduits are an electrical conduit.

Is the split conduit used as a service system?

Very often you will find that users get a split version to place on damaged or broken conduits. Slots placed along the length of the product can be easily installed on other cables or conduits to restore or improve protection.