We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

Application of Flexible Wire Conduit

What is flexible pipe

It refers to metal round pipe and chemical pipe. Besides, flexible pipes have two types, A and B, and their uses are different. Type A pipe is used for the internal wall of the building, while type B pipe is used for the external wall of the building, which cannot be confused.

-

Material: Stainless steel

Color: Silver

Product Type: hose

Application: Shipbuilding

Stainless steel optical fiber tube

-

Material: Stainless steel strip (201, 304)

Color: Silver

Product Type: hose

Application: Shipbuilding

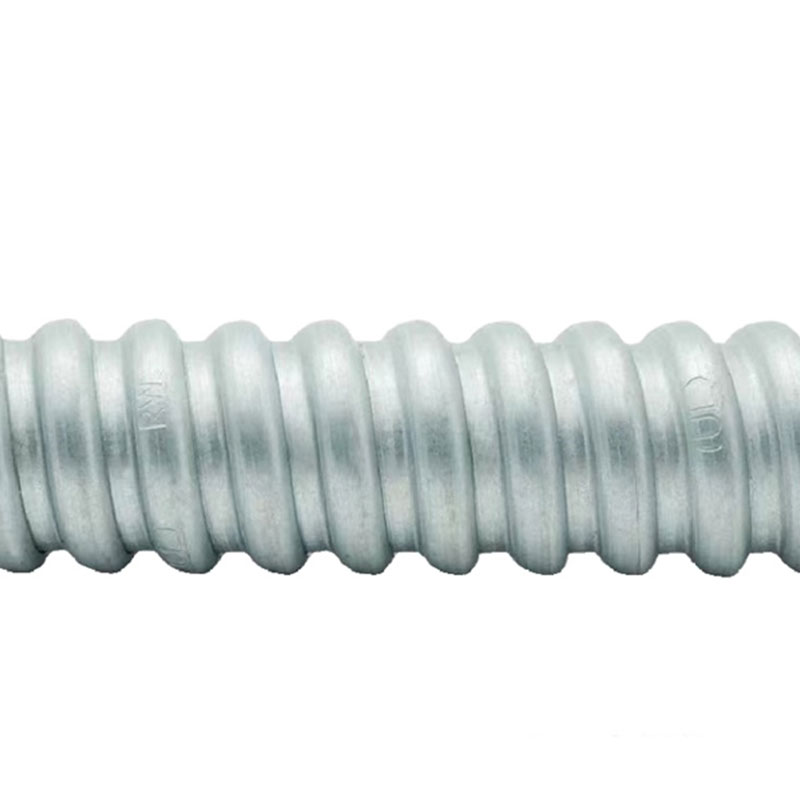

American standard galvanized metal conduit

-

Material: PVC and 304 stainless steel

Color: black (other colors available on request)

Working Temperature: -40℃~+80℃

Type: Coated catheter

Application: electrical installation, industrial

PVC Jacked Galvanized Corrugated Flexible Metal Conduit

-

Material: Galvanized steel

Color: silver gray

Application: Machine

Certification: RoHS,CE

Temp Range: -50 to +300 Degrees C

IP Rating: IP40 (Conduit) / IP40 (Conduit Plus Fittings)

Galvanized steel flexible conduit

-

Material: Galvanized steel strip + PVC plastic coating

Color: black, grey etc

Application: thermal power plant

Type: PVC Flat Pack Hose

Liquid tight flexible conduit

-

Raw material:: Galvanized Stainless Steel

Color: Black,grey etc

Type: Conduit

Surface: PE overmolding

Low smoke zero halogen flexible conduit

-

Raw material:: Galvanized steel strip with PVC coated

Color: Black,grey etc

Type: Conduit

Surface: PE overmolding

Temperature: -20°C- -120°C

LSOH liquid tight flexible conduit

-

Material: PVC coating

Color: Yellow

Product Type: hose

Wholesale customized natural gas pipe

-

What Is A Flexible Wire Conduit

Flexible wire conduit is an important part of any wiring system. It helps to protect the wires from damage and provides a way to route the wires where they need to go.There are many different types of flexible wire conduit available on the market today. The most common flexible conduit type is made from PVC, but there are also have conduit

types made from metal, fiberglass, and even Kevlar.

PVC is the most common type of flexible wire conduit because it is relatively inexpensive and easy to work with. However, it is not as durable as some of the other options.

Metal conduit is more expensive than PVC, but it is also more durable. It is important to note that metal conduit can be difficult to work with and install.

Fiberglass or Kevlar conduit is more expensive than PVC or metal, but it has a number of advantages. It is very strong and durable, making it ideal for high-traffic areas. It is also non-conductive, so it will not cause interference with electronic equipment. -

Advantages of flexible wire conduit

Some of the advantages of flexible wire guides are:

- Easy to install and remove

- Can be used for various applications

- Ideal for use in tight spaces

- Resistant to abrasion, chemical and thermal damage

A flexible wire conduit is a conduit used to protect and route electrical wires. It is made of flexible material and can be bent or shaped into different configurations.

Flexible wire conduit offers several advantages over other types of conduit, such as PVC pipe. It's easier to install because it doesn't require accessories or special tools. It is also more resistant to damage from shock or vibration.

-

How to install flexible wire conduit

Installing flexible electrical conduit is a great way to protect the electrical wiring in your home from damage. Flexible conduit is easy to install and can be found at most hardware stores.

Here are the steps to follow to install a flexible wire conduit:

1. Use a hacksaw to cut the conduit to the desired length.

2. Install the conduit by passing the conduit through the hole in the wall or ceiling. Make sure the conduit is snug against the wall to avoid sagging.

3. Secure the end of the conduit with electrical tape or cable ties.

4. Connect the wires to the receptacles or devices where they will be installed. Make sure all connections are secure so they don't loosen over time.

A flexible wire conduit is a plastic tube used to protect electrical wires.

The conduit is flexible so it can pass through walls, ceilings and floors. It is also fire resistant and does not produce toxic fumes when burned.

Conduit is available in different diameters and lengths. The most common sizes are 3/4" and 1" diameter. The length of the catheter will depend on the project you are working on.

Application of Flexible Wire Conduit

We are a professional PPR pipe manufacturer.LUELLYA manufactures PPR pipes using quality proven materials from our reliable supplier network, whose consistent material quality ensures consistent manufacturing cycles. Our PPR pipes are ready to be installed wherever they are delivered, as they have passed all quality standards through comprehensive testing in our full facility.

We reduce waste build-up and pollution in our manufacturing process by adhering to strict production standards and using recyclable PPR. Rigorous inspections are carried out at every stage to prevent hygiene and quality issues with our PPR pipes, ensuring product safety and quality are maintained while in use.