We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

Guidelines for Rigid Metal Conduit

Guidelines for Rigid Metal Conduit

Rigid Steel Conduit (RSC) Protected by NEC Article 344, threaded raceways of circular cross-section designed for physical protection and routing of conductors and cables, and used as equipment ground conductors when installed, their integral or associated couplings and appropriate accessories.

RSC galvanized steel conduit has the thickest walls of any steel raceway. It can be used with one piece or straight thread couplings. Electroline's hot-dip galvanized electrical rigid steel conduit (UL6) provides excellent wire protection, strength, safety and ductility.

-

Material: Stainless steel

Color: Silver

Product Type: hose

Application: Shipbuilding

Stainless steel optical fiber tube

-

Material: Stainless steel strip (201, 304)

Color: Silver

Product Type: hose

Application: Shipbuilding

American standard galvanized metal conduit

-

Material: PVC and 304 stainless steel

Color: black (other colors available on request)

Working Temperature: -40℃~+80℃

Type: Coated catheter

Application: electrical installation, industrial

PVC Jacked Galvanized Corrugated Flexible Metal Conduit

-

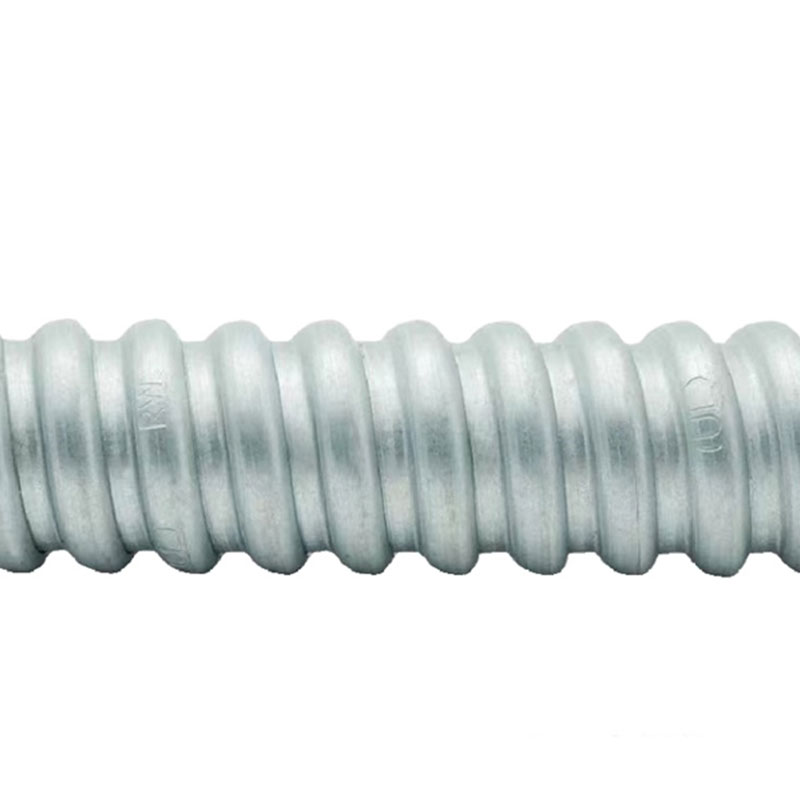

Material: Galvanized steel

Color: silver gray

Application: Machine

Certification: RoHS,CE

Temp Range: -50 to +300 Degrees C

IP Rating: IP40 (Conduit) / IP40 (Conduit Plus Fittings)

Galvanized steel flexible conduit

-

Material: Galvanized steel strip + PVC plastic coating

Color: black, grey etc

Application: thermal power plant

Type: PVC Flat Pack Hose

Liquid tight flexible conduit

-

Raw material:: Galvanized Stainless Steel

Color: Black,grey etc

Type: Conduit

Surface: PE overmolding

Low smoke zero halogen flexible conduit

-

Raw material:: Galvanized steel strip with PVC coated

Color: Black,grey etc

Type: Conduit

Surface: PE overmolding

Temperature: -20°C- -120°C

LSOH liquid tight flexible conduit

-

Material: PVC coating

Color: Yellow

Product Type: hose

Wholesale customized natural gas pipe

-

What is Rigid Metal Conduit?

Rigid metal conduit (RMC) is a type of electrical conduit made from rigid steel or aluminum. It is often used in industrial applications as an alternative to other types of conduit, such as PVC Conduit or EMT. RMC is more durable and has a higher tensile strength than other types of conduit, making it ideal for use in areas where there is a risk of damage or where high temperatures are a concern.

Rigid metal conduit (RMC) is a type of electrical conduit made from rigid steel or aluminum. It is commonly used in commercial and industrial applications to protect electrical wiring.Rigid metal conduit is available in a variety of sizes and lengths.

Rigid Steel Conduit (RSC) Protected by NEC Article 344, threaded raceways of circular cross-section designed for physical protection and routing of conductors and cables, and used as equipment ground conductors when installed, their integral or associated couplings and appropriate accessories.

RSC galvanized steel conduit has the thickest walls of any steel raceway. It can be used with one piece or straight thread couplings. Electroline's hot-dip galvanized electrical rigid steel conduit (UL6) provides excellent wire protection, strength, safety and ductility.

-

Installation Guidelines for Rigid Metal Conduit

Step 1: Anchor Boxes. Anchor metal boxes to the wall with screws. ...

Step 2: Measure Conduit. Once you install the boxes, measure the conduit for cutting. ...

Step 3: Cut Conduit. Cut the conduit to fit with a hacksaw. ...

Step 4: Slide in Conduit. Slide the conduit into a fitting and tighten the setscrew. ...

Step 5: Anchor Conduit.

-

Benefits of Using Rigid Steel Conduit

Rigid metal conduit is strong, durable and corrosion resistant. It provides excellent impact, crush and wear protection. It can be used in wet or dry places.

Rigid metal conduit is an excellent choice for protecting electrical wires in industrial and commercial applications. It can be used indoors or outdoors, in exposed or hidden locations.

Rigid Metal Conduit (RMC) is a common electrical conduit, but if you're not an electrician or work in the construction industry, you may not be familiar with it.

Rigid metal conduits are made of galvanized steel or aluminum and are required in many commercial and industrial applications. It is durable and ideal for areas where shock or vibration could damage other types of conduit. RMC can also be used in corrosive environments.

Why Choose Our Home Rigid Metal Conduit?

We are a professional PPR pipe manufacturer.LUELLYA manufactures PPR pipes using quality proven materials from our reliable supplier network, whose consistent material quality ensures consistent manufacturing cycles. Our PPR pipes are ready to be installed wherever they are delivered, as they have passed all quality standards through comprehensive testing in our full facility.

We reduce waste build-up and pollution in our manufacturing process by adhering to strict production standards and using recyclable PPR. Rigorous inspections are carried out at every stage to prevent hygiene and quality issues with our PPR pipes, ensuring product safety and quality are maintained while in use.

If you would like to know more about liquid tight flexible conduit or any of our metallic and non-metallic flexible conduits, please do not hesitate to contact us. The team is here to help you and will be more than happy to share their expertise.