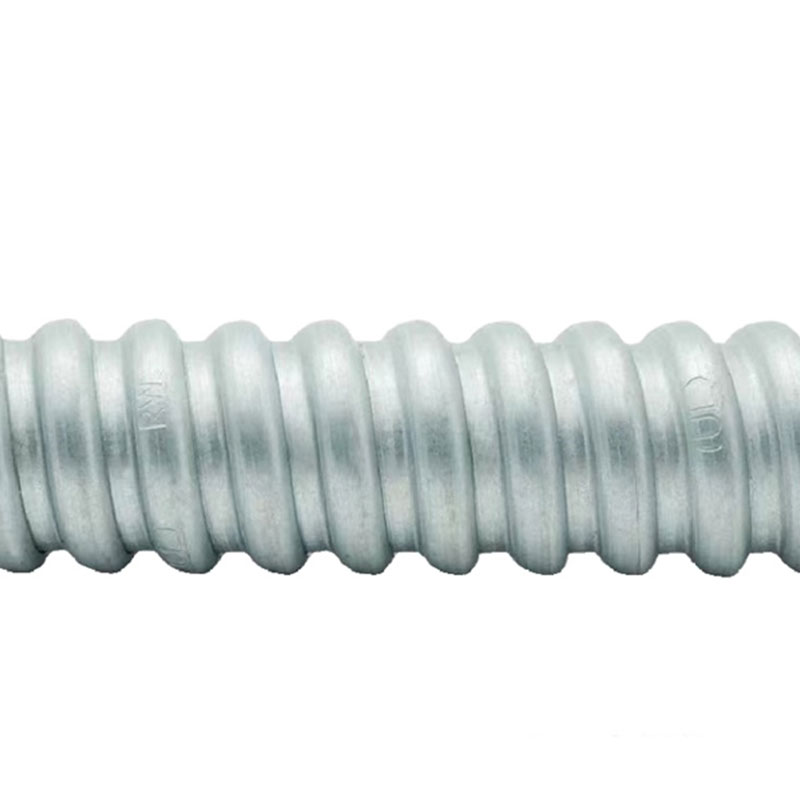

We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

Stainless steel conduit application guide

Stainless steel conduit application guide

When it comes to choosing the right conduit for your application, stainless steel conduit should be at the top of your list. Here’s why:

Stainless steel is corrosion resistant, making it ideal for use in harsh environments or in areas where conduit will be exposed to salt water or other corrosive materials.

Stainless steel is strong and durable, able to withstand high temperatures and heavy impacts.

Stainless steel is non-magnetic, which is important for applications where EMI/RFI shielding is required.

Stainless steel conduit is available in a variety of sizes and styles to fit your specific application needs.

Stainless steel conduit is a great option for applications where corrosion resistance is important, such as in food and beverage processing, marine environments, and chemical plants. While it is more expensive than other types of conduit, it offers superior durability and resistance to harsh chemicals and cleaners.

Various sizes of stainless steel conduit

Stainless steel conduit is available in a variety of sizes, from 1/4-inch to 6 inches. The most common types are 3/4-inch and 1-inch.

The main difference between the two types is the amount of space they take up. 3/4-inch conduit is typically used for electrical wiring, while 1-inch conduit is used for larger cables, such as those used for data or fiber optic lines.

While 3/4-inch and 1-inch conduit are the most common sizes, there are other options available, such as 2-inch and 4-inch conduit. These larger sizes are typically used in industrial or commercial applications.

Stainless steel conduit is an excellent choice for a variety of applications due to its durability, corrosion resistance, and aesthetic appeal. It is available in a wide range of sizes to accommodate different needs.

1/2-inch: This size is the most common and is typically used for general wiring projects.

3/4-inch: This size is often used for heavier-duty applications such as outdoor wiring.

1-inch: This is the largest size of stainless steel conduit and is typically used for industrial applications.

Precautions for stainless steel conduit

Stainless steel conduit is an excellent choice for corrosive or wet environments, as it is resistant to rust and corrosion. However, there are a few precautions that should be taken when installing or working with stainless steel conduit to ensure its longevity.

When installing stainless steel conduit, be sure to use dielectric unions or fittings at all connections. This will prevent galvanic corrosion, which can occur when dissimilar metals are in contact with each other in the presence of an electrolyte (such as water).

If you need to cut stainless steel conduit, be sure to use a cutting wheel designed for stainless steel. Regular cutting wheels can cause the stainless steel to work-harden and become brittle, increasing the risk of breakage.

Finally, when working with any type of electrical equipment, always take proper safety precautions and follow all local codes and regulations.