We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

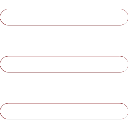

Thermo-fusion manual heating device plastic pipe welder

Humidity: 45%~95%

Safety level: more than 1MΩ

Weight (kg): 0.95 kg

Ambient temperature: -20°C ~ 50°C

Voltage: 176V-245V

Welding area: 0-10mm diameter

- Specification

- Information

-

PRODUCT PARAMETERS

Thermo-fusion manual heating device plastic pipe welder

Pipe diameter/ MM Hot melt time/ S Processing time/ S Cooling time/ MIN 20 5 4 3 25 7 4 3 32 8 4 4 40 12 6 4 50 18 6 5 63 24 6 6 75 30 10 8 90 40 10 8 110 50 15 10 160 60 25 20 -

THERMO-FUSION MANUAL HEATING DEVICE PLASTIC PIPE WELDER

This product is suitable for the connection of PP-R, PE, pp-c and other thermoplastic pipes.The product has the advantages of accurate temperature control, high reliability, good safety, and a unique non-stick plastic mold release process. User-friendly operation.

Our factory has the following series of products:

SH-1 (800W with die head Φ25 and Φ32),

SH-2 (1000W with die head Φ20, Φ25, Φ32, Φ40, Φ50, Φ63),

SH-5 (2200W, die head Φ160).

FEATURES

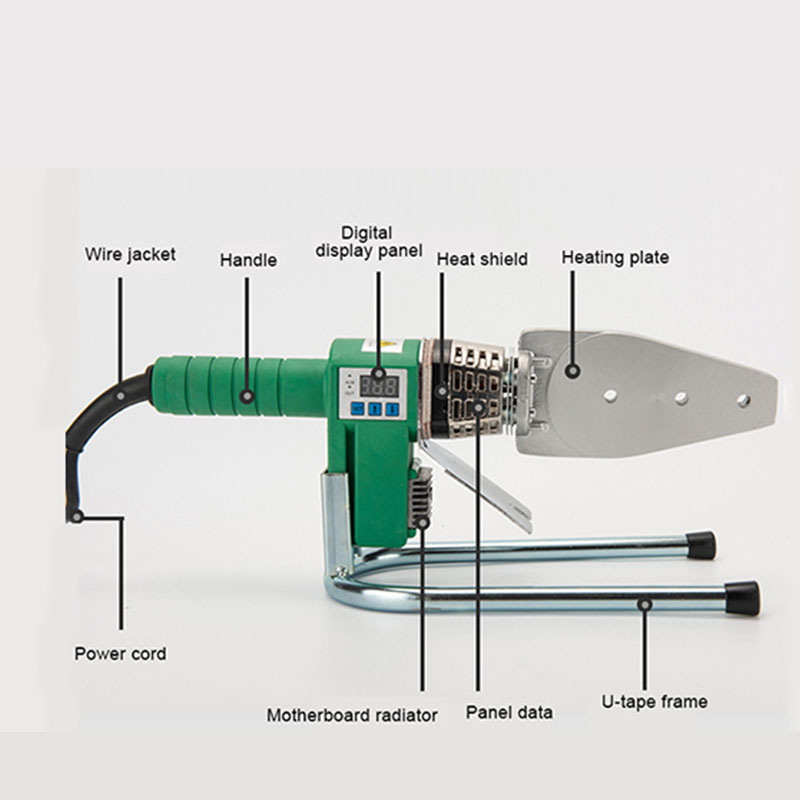

• Automatic temperature control • High yield and low material waste • Vacuum system for thick coating • Long time working performance is stable. OPERATION STEPS

1.Preparatory work 2.Cutting the PPR pipe ▪ Choose the suitable sockets and install prepare the fusion machine,tools and fusion material ▪ Cutting the requested length with the specified PPR pipe cutter 3.PPR pipe Cleaning 4.Measure Depth ▪ Cleaning the PPR pipe welding Surface ▪ Marking the suitable depth for specified PPR pipe 5.Heating 6.Fusion and Connecting ▪ Push the PPR pipe and PPR fitting into the welding tool up to the welding depth ▪ Push the heated pipe and fitting exactly and suitable adjustment, adjustment should be finished within 3 seconds