We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

-

Waterproof metal 304 stainlesssteel 90 degree cable connector

Read more -

Non-metallic liquid tight connector -- 90 degree elbow type

Read more -

Waterproof metal 304 stainlessSteel 90 degree cable connector

Read more -

Liquid Tight Flexible Conduit Connector-Metal Elbow Connector

Read more -

Liquid tight flexible conduit connector--Straight connector

Read more -

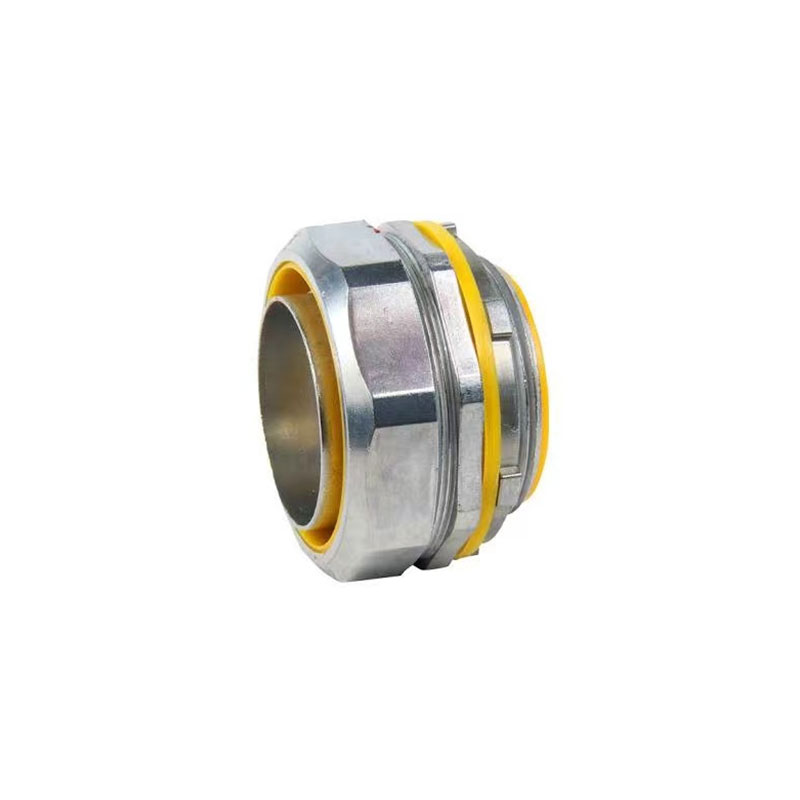

Waterproof Flexible Conduit Connector

Read more -

Explosion-Proof Metal Joint Sheep Horn Armored

Read more -

DPY Type Stainless Steel Tee Joint

Read more -

IP68 PG7 Waterproof Stainless Steel Cable Glands

Read more -

Galvanized Split Type Metal Hose Fittings Waterproof IP66

Read more -

Zinc Alloy Straight Fitting

Read more -

Metal Straight Stainless Steel Outer Square Plug

Read more

Metal Pipe Tube Connectors/Fittings

Metal Pipe Tube Connectors/Fittings are kinds of high-quality flexible pipe in modern industrial pipeline. It is mainly composed of bellows, mesh sleeves and Fittingss. Its inner tube is a spiral or annular thin-walled stainless steel bellows, and the outer mesh of the bellows is woven from stainless steel wires or steel strips according to certain parameters.

There are many types of Fittings products on the market now, which are characterized by outstanding flexibility, safety and reliability, and the overall ductility is also quite good, and the Fittings products also have different functions in terms of use.

Nowadays, such parts play a very important role in many industries, and metal hose Fittingss have very good processing and forming properties, and are excellent in corrosion resistance, acid and alkali resistance and fatigue strength. The performance of hose Fittings products is very diversified.

Different Types of Metal Pipe Tube Connectors/Fittings

DPJ Pipe Fittings

Structure and Features:

DPJ external thread end connection metal hose Fittings is an extension product of JB/GQ 0552 /83 D95-5 metal Fittings;

The metal Fittings is made of die-cast zinc alloy material, and the surface is galvanized, frosted, or chrome-plated; the structure is compact, without pores, and has high strength. Reliable connection with metal hose and beautiful appearance;

This metal Fittings is an end connection type, which is used to connect the metal hose to the straight line connector on the box;

Suitable for metal hoses: JS type, JSH type, JSB type, JSHG type;

It is recommended to use inch metal hose fittings or metric thread metal fittings;

Various non-standard metal hose Fittingss and special metal Fittingss can be customized.

DKJ Pipe Fittings

Structure and Features:

DKJ ferrule type metal hose Fittings can connect unthreaded steel pipe and hose, save the threading process, just screw in the screw;

The metal Fittings is made of die-cast zinc alloy material, and the surface is galvanized, sanded or chrome-plated; the structure is compact and the strength is high. The connection between the steel pipe and the metal hose is reliable and the appearance is beautiful;

This metal Fittings is a ferrule type, which is used to connect the metal hose to the unthreaded steel pipe;

Suitable for metal hoses: JS type, JSH type, JSB type, JSHG type;

Suitable for steel pipes: thin steel wire pipes, black and white iron pipes (water, gas pipes);

When choosing DKJ ferrule type metal Fittings, please pay attention to the specification and size of the connecting steel pipe hose.

DGJ Pipe Fittings

Structure and Features:

DGJ self-fixing metal hose Fittings can connect unthreaded steel pipe or unthreaded equipment outlet with the hose, saving the threading process;

The metal Fittings is made of die-cast zinc alloy material, and the surface is galvanized, sanded, or chrome-plated; the structure is compact and the strength is high. The connection between the steel pipe and the metal hose is reliable and the appearance is beautiful;

This metal Fittings is self-fixing, used to connect the metal hose to the unthreaded steel pipe or the unthreaded equipment outlet;

Suitable for metal hoses: JS type, JSH type, JSB type, JSHG type;

Suitable for steel pipes: thin steel wire pipes, black and white iron pipes (water, gas pipes);

When choosing DGJ self-fixing metal hose Fittingss, please pay attention to the specifications and dimensions of the connecting steel hoses.

90 degree Pipe Fittings

90 degree elbow Fittings: thread specification: inch thread (G)

Product material: A, C, F parts are made of high-quality steel. D is made of die-cast iron sheet.

Color Type: Metallic (Silver White)

Working temperature: -40 degrees to 100 degrees, can be heat-resistant up to 120 degrees in an instant.

Product Features:

1. After joining, it is 90 degrees with the box body, thickened zinc alloy, beautiful appearance, compact structure and high strength.

2. In addition to the following standard specifications, the size and thread standard can be arbitrarily changed according to requirements.

Y-joint Pipe Fittings

Structure and Features:

Y-shaped three-way metal hose connector, one end of the connector is connected to the thin steel wire tube, and the other end of the metal connector is connected to the metal hose:

The metal Fittings is made of die-cast zinc alloy material, and the surface is galvanized, sanded, or chrome-plated; the structure is compact, no pores, and high strength. Reliable connection with metal hose and beautiful appearance;

Suitable for metal hoses: JS type, JSH type, JSB type, JSHG type, complete specifications;

Various non-standard metal hose Fittingss and special metal Fittingss can be customized.

T-joint Pipe Fittings

Structure and Features:

T-shaped three-way metal hose connector, one end of the connector is connected to the thin steel wire tube, and the other end of the metal connector is connected to the metal hose;

The metal Fittings is made of die-casting zinc alloy material, the surface is galvanized, sanded or chrome-plated, the structure is compact, there is no air hole, and the strength is high. Reliable connection with metal hose and beautiful appearance;

Suitable for metal hoses: JS type, JSH type, JSB type, JSHG type, complete specifications;

Various non-standard metal hose Fittingss and special metal Fittingss can be customized.

Stainless Steel Pipe Fittings

The end-connected Stainless Steel Hose Pipe Fittings is cast by standard stainless steel. The end-connected stainless steel hose joint has a tight structure, no air holes, high strength, reliable connection with the stainless steel hose, and beautiful appearance.

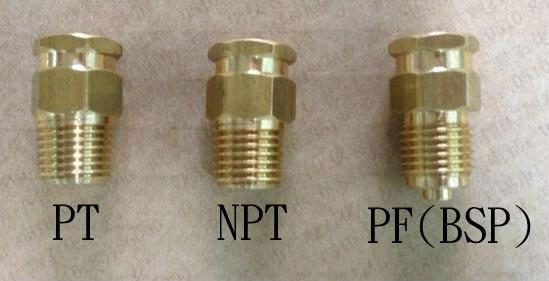

The Meaning and Difference of NPT, PT, G, and metric threads of Metal Pipe Fittings

There are many types of threaded Fittingss for metal hoses. Many people do not understand this very well. Now let's explain and explain these thread symbols:

NPT, PT, G are all pipe threads

NPT is the abbreviation of National (American) Pipe Thread, NPT is the American tapered pipe thread, used for sealing. The 60-degree tapered pipe thread belonging to the American standard is used in North America, and the national standard can be found in GB/T12716-1991;

PT is the abbreviation of Pipe Thread. It is a 55-degree sealed conical pipe thread. It belongs to the Wyeth thread family. It is mostly used in Europe and the Commonwealth of Nations. It is often used in the water and gas pipe industry. -2000.

G is a 55-degree non-threaded sealing pipe thread, which belongs to the Whitworth thread family. G is the general name for pipe threads, and the division of 55 and 60 degrees is functional, commonly known as pipe circle. That is, the thread is machined from a cylindrical surface.

Metric threads are expressed by pitch, and American and British threads are expressed by the number of threads per inch, which is the biggest difference between them.

The metric thread is a 60-degree equilateral thread, the inch thread is an isosceles 55-degree thread, and the American thread is 60 degrees.

Metric threads are in metric units, and American and British threads are in imperial units.

Pipe threads are mainly used to connect pipes, and the inner and outer threads are closely matched, and there are two types of straight pipes and tapered pipes. Nominal diameter refers to the diameter of the connected pipe, obviously the thread diameter is larger than the nominal diameter.

Five Elements for the Selection of Metal Pipe Fittings

(1) Size of the nominal diameter of the hose, the selected joint types mainly include flange connection, threaded connection, quick connector connection and the size and length of the metal hose.

(2) Pressure: According to the actual working pressure of the hose, check the nominal diameter and pressure gauge of the corrugated metal hose to decide whether to use the stainless steel mesh type metal hose.

(3) Medium: The chemical properties of the medium conveyed in the hose determine the material of each part of the hose according to the corrosion resistance of the hose material.

(4) Temperature: the working temperature and range of the medium in the hose, and the ambient temperature when the hose is working. When the temperature is high, the pressure after temperature correction must be determined according to the working pressure and temperature correction coefficient of the metal hose at high temperature, so as to determine the correct pressure level.

(5) Status: According to the status of the hose, the correct use and installation method and the optimum length of the hose during settlement compensation, the length calculation of the hose in various motion states, and the minimum bending times and minimum bending radius of the hose and other factors, the parameters are correctly selected for the length of the hose and installed correctly.

Factors to Consider when purchasing Metal Pipe Fittings

The use of quick metal hose joints should comply with relevant industrial technical specifications, and the following factors should be considered when purchasing:

One is to select the appropriate structure and material according to the corresponding use environment.

Including factors such as the humidity conditions of the operating environment, the condition of dust and whether it is easy to corrode, etc., to comprehensively consider the type, body material and sealing material of the quick connector selected. If metal hose fittings are exposed to chemically corrosive environments, such as salt water or sour gas, only stainless steel or brass fittings are required.

The second is to select the appropriate structure and material according to the type and temperature of the fluid.

Different types of fluids, body materials and sealing materials need to be equipped with different metal hose quick connectors. If it is air, steel metal joints are recommended; if it is water, brass or stainless steel metal joints are recommended.

Therefore, when purchasing metal hose joints, the consistency of the chemical composition, temperature and pressure of the fluid and the pipe joint should be considered. In order to avoid the erosion of mineral oil and synthetic fluid, most pipe joints are electroplated. If there is a rubber sealing ring as a part of the pipe joint, it must be ensured that the material of the sealing ring is suitable for the fluid.

The third is to select a suitable metal hose joint according to the structure of the automatic opening and closing valve.

The structure of the valve usually has two-way switch type, one-way switch type and two-way open type. When purchasing metal hose fittings, you have to figure out in advance which type it is. In addition to the two-way switch type, fluid may flow out of the piping during separation, so it is necessary to select a quick connector with a valve structure suitable for the piping application.

The crimped metal hose joint requires less space than the detachable pipe joint, and the weight is also 15% smaller than the detachable type, which can use the effective space more economically and reduce the volume and weight of the entire system. Permanent crimping pipe joints should be used for high-pressure pipelines, because detachable joints are not easy to install on hoses reinforced with four or six layers of spiral wire.

Selection and Installation of Corrugated Metal Hose

The selection of corrugated metal hoses should comprehensively consider the following factors: medium properties, diameter and pressure, joint form, displacement method, minimum bending radius and length, etc. Improper selection may cause early failure of metal hoses, resulting in serious personal injury or death. Equipment accident.

1. Type: In order to compensate for pipeline displacement, installation deviation and foundation settlement, absorb vibration and reduce noise, etc., annular corrugated metal hose should be used; for occasions where the pressure is high but displacement and vibration do not occur frequently, spiral corrugated pipe should be used Metal Hose.

2. Medium properties-material: Choose metal hoses of suitable materials according to the corrosiveness and temperature of the medium.

3. Joint form: spherical type, cone type, flat joint type, quick joint type, pipe thread type, flange type and nozzle type.

4. Length of metal hose:

5. Length of metal hose for vibration reduction and noise reduction

6. Length of metal hose for radial displacement

Precautions for installation of corrugated metal hose:

The metal hose should be set at the connection between the front valve of the tank and the pipeline to form a soft connection between the storage tank and the pipeline.

When the pipeline process in front of the tank is under pressure, a control valve should be installed when installing the metal hose.

When installing metal hoses, prevent welding slag from splashing on the hose.

The method of tightening flanges and bolts should not be used to eliminate installation deviation.

The height of the metal hose from the natural ground after installation should be greater than its lateral displacement compensation.

There should be no brackets or supports on the metal hose.

Metal Pipe Tube Connectors/Fittings Manufacturer

Our products: An overview of our metal connectors

If you're in need of a metal connector, look no further than our selection here at Our Company. We have a wide variety of connectors to choose from, all made with high-quality materials. Whether you need a small connector for a delicate project or a heavy-duty one for something more rugged, we have just what you're looking for.

Take a look at our selection and find the perfect connector for your next project!

The manufacturing process: How metal connectors are made

In order to make metal connectors, a few steps must be followed in the manufacturing process. First, the raw materials must be gathered. Second, the raw materials must be melted and formed into the desired shape. Third, the metal must be cooled and then cut to size. Fourth, any final treatments must be completed. Finally, the connectors are inspected and packaged for shipping.

Reliable metal connector manufacturer and supplier

LUELLYA is a reliable metal connector manufacturer and supplier, specializing in the design and production of high quality connectors for a variety of industries. With over 30 years of experience, Anchor has the knowledge and expertise to provide superior products and service to their customers. In addition to manufacturing top-quality connectors, Anchor also offers a variety of other services such as custom design, engineering support, and prototyping. Whether you need a few hundred connectors or millions, Anchor is your one-stop shop for all your connector needs.

Metal connector manufacturers and suppliers are important for many industries

Metal connector manufacturers and suppliers are important to many industries because they provide the necessary components for connecting two or more pieces of metal. Metal connectors can be used in a variety of applications, including electrical, plumbing, and construction. There are many different types of metal connectors available on the market, so it is important to choose a reputable manufacturer or supplier that offers quality products at competitive prices.