We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

-

Liquid Tight Flexible Conduit Connector-Metal Elbow Connector

Read more -

Liquid tight flexible conduit connector--Straight connector

Read more -

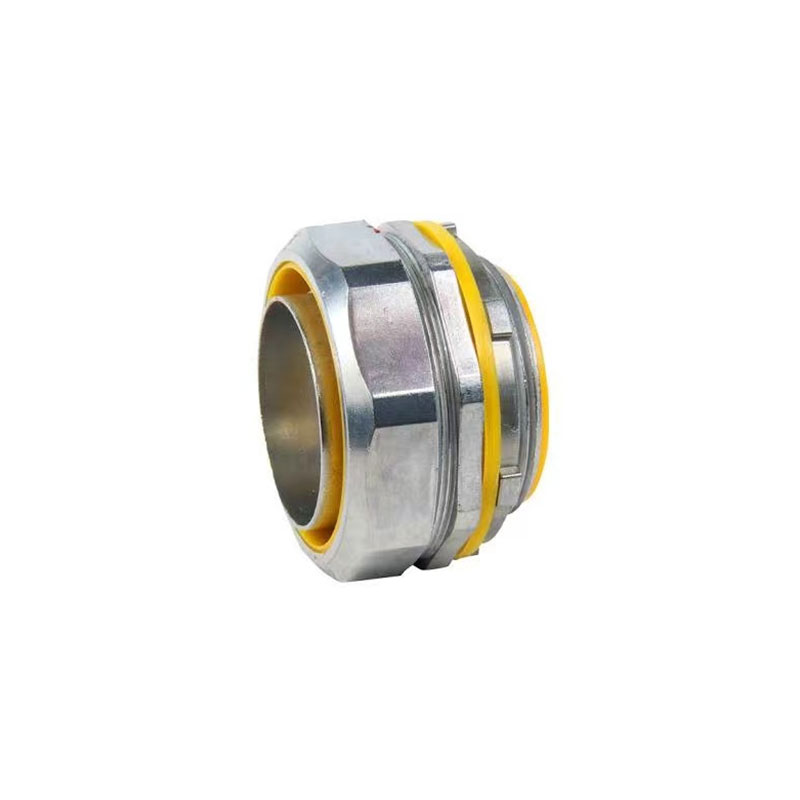

Waterproof Flexible Conduit Connector

Read more

Introduction: what is zinc alloy?

Zinc alloys are mixtures of zinc and other elements, usually copper, aluminium, magnesium, cadmium or titanium. Zinc alloys have good strength and ductility and are used in die-casting (such as for making toys and coins) and in wrought form (such as galvanized steel). They are also used in zinc plating to protect iron and steel from corrosion.

Zinc alloys: composition and properties

Zinc alloys are used in a variety of applications due to their unique composition and properties. The most common zinc alloy is brass, which is composed of copper and zinc. Other popular alloys include bronze (copper and tin) and nickel silver (copper, nickel, and zinc). Zinc alloys are known for their high strength and corrosion resistance.

What are the benefits of using zinc alloy connectors?

If you’re looking for a strong and durable connector, zinc alloy is a great option. It’s not only strong, but also resists corrosion better than other materials. Additionally, zinc alloy is a good conductor of electricity and heat, which makes it ideal for electronic applications. It’s also easy to cast and machine, which makes it a versatile option for manufacturers.

Your professional metal connector manufacturer

LUELLYA manufactures metal connectors using quality proven materials supplied by our network of reliable suppliers whose stable material quality ensures a consistent manufacturing cycle. Our metal connectors can be installed anywhere as they pass every quality standard in comprehensive testing at all our facilities.

We conduct rigorous inspections at every stage to prevent hygiene and quality issues with our metal connectors, ensuring that the safety and quality of our products are maintained when in use.