We are specialized in manufacturing all kinds of metal conduit,

Hangzhou Fanyumeier Trading Co., Ltd

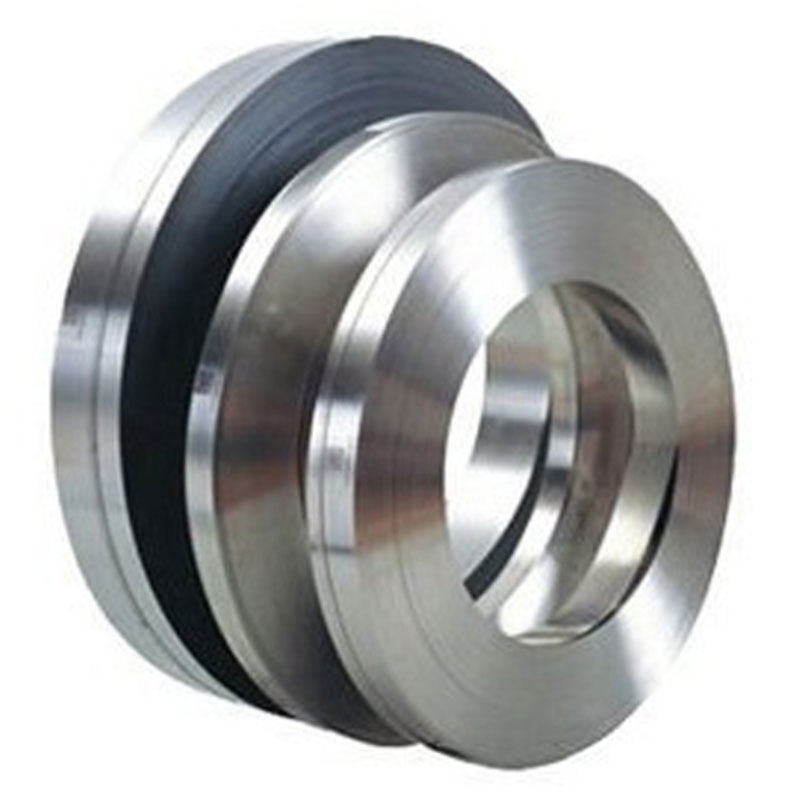

Introduction: what is steel strip?

In metallurgy, steel strip is a flat-rolled product that is produced by hot-rolling a sheet of steel into a thinner gauge. It can also be made by cold-rolling process. Steel strip is available in a variety of widths and thicknesses, and it can be cut to length as needed. The main use for steel strip is to make springs, but it is also used in the automotive and construction industries.

Steel strip is made from annealed sheet steel that has been passed through rollers to reduce its thickness. The width of the strip depends on the width of the sheet from which it was cut. Thestrip is then heat treated to improve its hardness and strength. Cold-rolled strip is made from hot-rolled sheet steel that has been passed through rollers at room temperature to reduce its thickness.

Steel strip in construction: its uses and benefits

Steel strip is a very versatile product that can be used in a wide variety of construction applications. Its benefits include its high strength-to-weight ratio, its resistance to corrosion and fire, and its ease of installation.

One common use for steel strip is as cladding on the exterior of buildings. This provides a durable, long-lasting finish that is resistant to both weathering and fire. Steel strip can also be used as flashing around doors and windows, or as trim for roofs and gutters.

Another popular use for steel strip is as reinforcement in concrete walls. The steel helps to strengthen the wall, resist cracking, and provide fire protection. It is also commonly used in the fabrication of prefabricated concrete panels.

Steel strip has many benefits that make it an ideal material for use in construction applications.

The steel strip manufacturing process

The steel strip manufacturing process is a multi-step process that involves heating, rolling, and cooling the steel to achieve the desired dimensions and properties. The first step in the process is to heat the steel to the appropriate temperature. This can be done in a furnace or by using other methods such as induction heating. The next step is to roll the steel through a series of rollers to achieve the desired thickness. Finally, the steel is cooled to room temperature.

There are several important factors that must be controlled during the steel strip manufacturing process to ensure quality results. These include temperature, pressure, speed, and alignment. By carefully controlling these variables, it is possible to produce high-quality steel strips with accurate dimensions and desired properties.